Ensuring machinery safety and compliance in industrial environments is essential to maintaining a safe workplace and reducing operational risks. Barrier Group provides free resources designed to help businesses assess and improve machine safety without compromising on efficiency or productivity.

Machine Guarding Checklist: Assess Your Equipment Safety

Machine guarding is a foundational element of workplace safety. Barrier Group’s machine guarding checklist enables you to evaluate your equipment systematically, ensuring all safety measures are in place. This checklist includes essential criteria to help you determine whether your machinery has the right level of guarding, including:

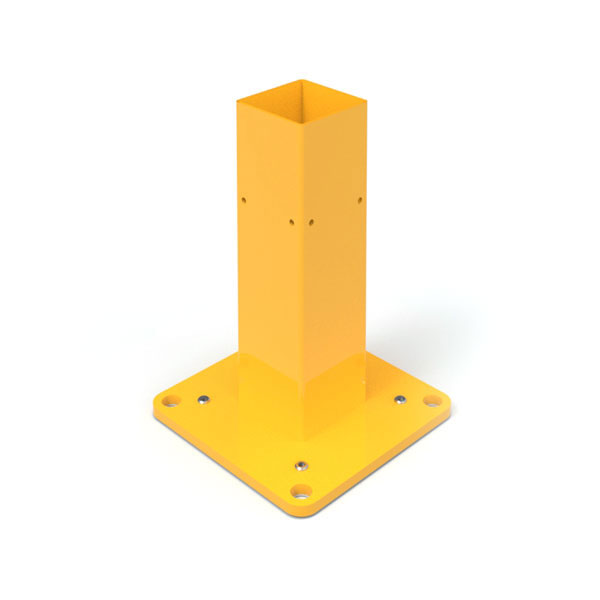

- Guard Placement: Proper guard placement ensures that dangerous parts of machinery are fully covered. Poorly placed guards can expose workers to unnecessary risks, making secure installation crucial for all hazard points.

- Accessibility: While guards must be protective, they should also allow safe access for maintenance. Poorly designed guards can force operators or maintenance staff to bypass them, increasing the risk of accidents. Accessible guards reduce this temptation, allowing workers to perform routine checks without compromising safety.

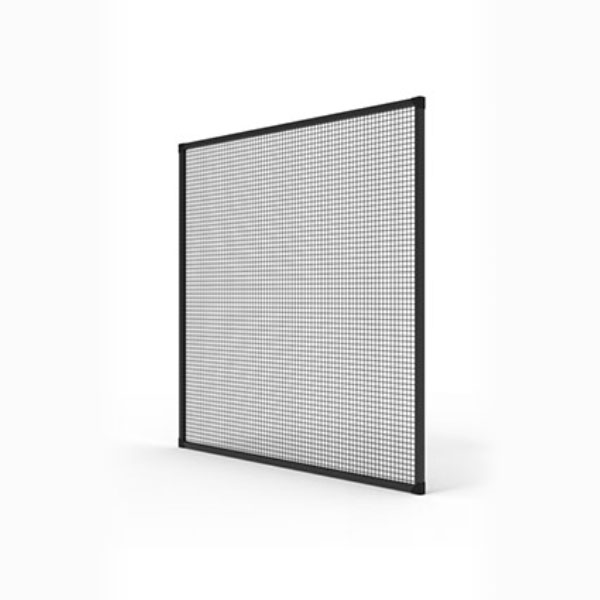

- Durability: Machinery guards should withstand the operational environment. High-wear areas or extreme conditions can cause guard materials to degrade over time, compromising their effectiveness. Durable guards minimize this risk, ensuring safety is maintained even in challenging environments.

- Visibility: In many operations, it is essential for operators to view certain parts of the machinery without direct exposure to hazards. Guards that balance visibility and protection allow workers to monitor machine functions while staying shielded from potential dangers.

With this checklist, businesses can evaluate their machine guarding to meet both safety regulations and operational efficiency, providing a well-rounded approach to machinery safety.

Risk Assessment Templates for Machine Guarding

Risk assessment is an integral part of creating a safe workplace. Barrier Group’s risk assessment templates guide you through a structured process of identifying and mitigating potential hazards associated with machinery.

What’s Included:

- Hazard Identification: This step involves identifying specific hazards, such as pinch points, sharp edges, and moving parts, that could cause injury. Recognizing these risks early allows for more proactive safety measures.

- Risk Estimation and Evaluation: Once hazards are identified, it’s critical to evaluate both the severity and likelihood of potential incidents. By quantifying risk, businesses can prioritize high-risk areas, ensuring that the most significant dangers are addressed first.

- Risk Reduction Measures: Based on the identified hazards, risk reduction involves selecting and implementing appropriate controls, such as specific guard types, emergency stop systems, and interlocks. These controls help to mitigate risks effectively, creating a safer environment for operators.

Barrier Group’s templates provide an efficient, step-by-step guide, ensuring a thorough evaluation of potential hazards and the implementation of appropriate safety controls.

Free Resources to Improve Machine Safety and Compliance

Barrier Group’s resources are designed to provide accessible, practical support for companies aiming to improve machine safety and achieve compliance. With tools such as the machine guarding checklist and risk assessment templates, businesses can quickly evaluate their current setup and identify improvements. Key resources include:

- Machine Guarding Checklist: A straightforward tool for assessing the adequacy of machine guarding, ensuring that all machinery is effectively protected.

- Risk Assessment Template: A comprehensive template for identifying and controlling machinery hazards, supporting a systematic approach to risk management.

These resources, available for download, offer a structured approach to evaluating machine safety and complying with safety standards, supporting companies in reducing workplace hazards effectively.

Please note that the information provided herein is for general informational purposes only and is not a substitute for professional advice. For specific guidance on compliance and safety measures under AS/NZS 4024 or other relevant standards, consult a qualified professional to assess your unique requirements and ensure full regulatory compliance in your situation.

About Barrier Group

Barrier Group is the leading Australian provider of industrial safety solutions, specialising in products and resources that help businesses safeguard their workforce and meet compliance standards. With a commitment to workplace safety, Barrier Group offers reliable solutions that protect workers and ensure regulatory adherence, establishing a safer work environment across industries.

We Can Help You With Machine Guarding Compliance

Contact us today to find out how we can help you achieve standards compliance and enhance the safety of your machinery.