JOST Australia

JOST Australia, a leading supplier of advanced transportation components within Australia, required a warehouse fit-out for their newly constructed head office facility in Laverton North. This initiative marked a pivotal step in the company's strategic expansion plan, aimed at optimising distribution efficiency and increasing storage capacity.

JOST Australia collaborated with Barrier Group to implement an end-to-end safety solution at their new facility. The project encompassed Barrier Group’s traffic management, machine guarding, signage and line marking solutions, being among Barrier Group’s largest line marking initiatives to date, demonstrating a commitment to operational safety and excellence.

- Location: Laverton North, Melbourne, Australia

- Complete: October 2025

- Visit: https://www.jostaustralia.com.au

The Problem

When JOST Australia set out to consolidate its products and associated brands under one roof, the company envisioned a purpose-built 14,000-square-metre facility designed for efficiency, safety, and scalability. To realise this vision, JOST required a comprehensive warehouse safety fit-out - one that not only safeguarded personnel but also met the operational demands of a large-scale, high-traffic environment.

Through early consultation and site evaluation, three key areas of concern were identified:

-

Pedestrian–Vehicle Interaction: The new facility included a number of designated pedestrian walkways, both around the perimeter and throughout active operational zones. These pathways were essential for staff movement between work areas but posed potential risks where pedestrian and vehicle routes converged.

-

Safe and Visible Access Points: Establishing robust, high-visibility pedestrian crossings and access points was crucial to ensure that employees could enter and exit operational zones safely and with clear right-of-way.

-

Segregation of Hazardous Zones: A dedicated area within the facility was designated for the storage and operation of hazardous equipment. This space required complete segregation from general work areas to eliminate the risk of accidental exposure or injury.

The Solution

By addressing these priorities, Barrier Group collaborated closely with JOST to deliver a tailored, compliant, and future-ready safety solution - reinforcing JOST Australia’s commitment to workplace safety and operational excellence.

Barrier Group Account Manager, Robbie, conducted an initial site visit to assess the facility layout, take detailed measurements, and gain a full understanding of JOST Australia’s operational safety requirements. Through close collaboration between the JOST and Barrier Group teams, a tailored end-to-end safety strategy was developed to ensure the facility was fully equipped, compliant, and operationally safe from day one.

The full scope of the safety product fit-out included:

-

Asset Protection

-

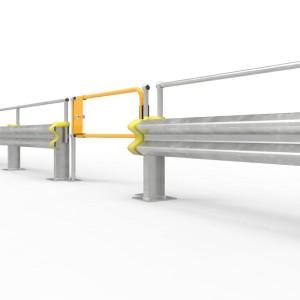

W-Beam Guardrail (with Ball-Fence) - Installation of heavy-duty w-beam barrier systems to clearly define pedestrian walkways and segregate them from forklift operating zones. The additional Ball-Fence doubled as a handrail for JOST employees as they navigated along the walkways.

-

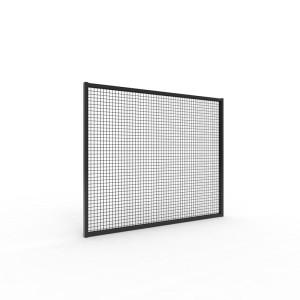

Facility Partitioning/Machine Guarding - Secure partitioning of hazardous equipment areas using ISF Machine Guarding to prevent unauthorised access, reach through, reach over, and reach under.

-

Bollards - Strategic placement of bollards to safeguard building infrastructure, and other safety equipment, from potential vehicle impact.

-

Swing Gates - High-visibility industrial swing gates at all key entry and exit points to promote safe navigation throughout the site.

-

Column Cushions - Heavy-duty, foam-filled column protectors were installed throughout the facility to safeguard key structural columns from potential vehicle impact.

-

-

Environment Control

-

Defined Walkways - Line Marking - Clear pedestrian pathways, crossings, and designated no-vehicle-access zones were established throughout the facility to promote safe and efficient movement of personnel.

-

Traffic Management - Custom Signs - Custom safety signage was installed throughout the interior and exterior of the facility to reinforce critical safety messages, guide pedestrian and vehicle movement, and ensure compliance with site-specific operational requirements. Each sign was tailored to enhance visibility and consistency across the warehouse environment.

-

Enhanced Visibility - Mirrors - Custom signage and safety features were strategically placed throughout the facility to provide employees and vehicle operators with improved visibility around loading and unloading zones, reducing the risk of accidents and supporting safe, efficient warehouse operations.

-

-

Pedestrian Guidance

-

Belt Barriers - Pilot 10 - Pilot 10 Belt Barriers were installed to manage pedestrian flow and restrict access where needed. Equipped with “Do Not Enter” belts and wall-mount attachments, these barriers provide a flexible, temporary solution for controlling access to roller doorways or other restricted areas, ensuring safety while maintaining operational efficiency.

-

The Challenges

Barrier Group and JOST Australia worked closely over a four-month period on the Laverton North project, addressing the complexities of a large-scale warehouse safety fit-out while preparing for the facility’s grand opening.

A key challenge was phased delivery. With installation occurring during JOST’s bump-in period, it was critical that interior line marking was completed first, allowing paint to cure in pedestrian walkways where vehicle traffic was present. This approach ensured safety and operational continuity throughout the process.

The project required careful planning and coordination, with over 100 hours of line marking spread across multiple weeks. Both teams maintained close communication to manage scheduling, particularly for the exterior areas of the facility, where persistent wet weather created delays. Line marking and signage installation had to be rescheduled as the paint required sufficient curing time, demonstrating the importance of flexibility and adaptive planning in large-scale industrial safety projects.

Client Response

JOST Australia was highly satisfied to have their new facility ready and fully compliant ahead of the grand opening. The team particularly valued Barrier Group’s clear communication, proactive planning, and adaptability in responding to evolving project requirements.

The success of the Laverton North project has established a strong foundation for an ongoing collaboration, with JOST Australia and Barrier Group now exploring the implementation of consistent safety layouts across additional facilities as the company continues its nationwide growth.

This collaboration highlights how strategic planning, tailored solutions, and hands-on expertise can deliver safe, operationally efficient, and fully compliant industrial environments.