Leading Transport Infrastructure Manufacturer

A Safer, Smarter Wheel Shop: How A Leading Transport Infrastructure Manufacturer Future-Proofed Safety Without Slowing Down Operations

Located in Ballarat, a company in transport infrastructure engineering and manufacturing has positioned itself as an industry leader. This organisation is dedicated to providing world-class engineering solutions and advanced manufacturing capabilities, positioning itself as a key player in the development and enhancement of critical infrastructure assets within Australia’s public transport network. This involves a strong track record in designing, building, and maintaining infrastructure that supports long-term operational performance.

This case study explores how the client addressed safety challenges in their Wheel Shop area by partnering with Barrier Group through distributor Blackwoods, using tailored traffic management and machinery guarding solutions.

- Location: Ballarat, Victoria

- Complete: May 2025

The Problem

When the client collaborated with Barrier Group, their goal was to boost pedestrian safety and enhance navigation within their wheelshop area. They were reevaluating safety protocols in high-traffic areas where pedestrians and vehicles operate closely together.

Their primary focus was to delineate the Wheel Shop's outer boundaries using a mix of fixed partitioning panels and swing-style gates. Besides permanent fencing, they also needed a more adaptable, temporary solution to allow for flexibility in areas that might require reconfiguration over time.

Considering the site's variability and the unique needs of each section; some installation areas required custom fitting, and they requested a Barrier Group representative to visit the site and evaluate the options accordingly, ensuring each component was suitable for its intended purpose.

The Solution

The approach for this unique project involved implementing an efficient traffic control system aimed at reducing the likelihood of injuries to both pedestrians and vehicles. By addressing this issue, the client could continue operating with peace of mind knowing their workers can safely navigate the facility and remain compliant with safety regulations.

Key elements of the project include:

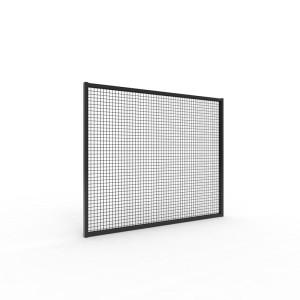

Machinery Guarding

Implementing industrial safety fencing enables a clear separation between pedestrian paths and active work areas in the wheel shop, minimising the likelihood of accidents caused by workers being in the same operating area as forklifts. With the expertise of the Barrier Group Product Solutions Team, this was carefully customised to fit the unique site requirements.

NoWeld Industrial Guardrail

A flexible guardrail offering the wheel shop a custom-fit solution to match the facility's unique dimensions and configuration, ensuring safety around vehicles and equipment. It additionally provides the facility with a temporary solution that can be effortlessly relocated if the wheel shop needs to be reconfigured in the future.

Ball-Fence Industrial Swing Gate

Installing swing gates at key transition points within the wheel shop to complement the NoWeld Guardrail System. These gates offer an efficient method to keep pedestrian paths unobstructed while permitting authorised staff and equipment to access designated areas as required.

Port-A-Guard Expandable Barrier

Gives workers in the wheel shop the ability to set up, move, and reconfigure a safety barrier on demand. The Port-A-Guard’s expandable design allows the team to quickly block off hazardous or restricted zones without the need for tools or permanent fixtures.

The Challenges

Prior to the commencement of works at the clients site, we had an on-site assessment to finalise the set-up of the installation. During this time we could make alterations which included some modification to the location of some of the partitioning fencing panels.

Moreover, throughout the evaluation process, it was also evident that the partitioning fencing would need some modifications to ensure it could be easily dismantled if access to the switchboard, situated near the pedestrian pathway, was required.

The installation, spanning over two days, proceeded without issues, with every component installed as planned. The client was pleased with the efficiency and the professionalism demonstrated by the Barrier Group installation team.

Client Response

By collaborating closely with the client through Blackwoods, Barrier Group delivered a tailored and effective safety solution for one of Australia’s most advanced transport infrastructure manufacturers. The result is a safer, more adaptable workspace where pedestrian safety and operational efficiency coexist. This case study highlights the importance of flexible safety systems that respond to real-world challenges, and how strategic partnerships can help future-proof workplace environments.

Trusted by Australia's Largest Brands for Workplace Safety Solutions. Could you be next?

Subscribe to stay connected with Barrier Group and discover cutting-edge safety solutions, updates, and industry insights!